新闻动态

相关阅读

新闻中心

SHOCKOKEE OR TILTOKEE

|

As a preamble to your initiating the use of Shockokee or Tiltokee * (or both) at your facility, please read the following: INTRODUCTION Shockokee, together with this simple implementation program, will allow you to monitor rough handling and reduce product damage via transport. Shockokee® • Provides immediate proof of rough handling • Is an impact sensor that adheres directly to your shipments See the Selection/Placement/Program Guide • Comes in a range of different sensitivities to cover a variety of applications See the Selection/Placement/Program Guide • Is a sensor that turns from white to red when an excessive impact occurs The Shockokee program encourages all handling personnel to be more careful, helps to reduce damage, pinpoints rough handling areas and is a Win-Win-Win for the shipper, carrier and consignee. *Tiltokee Tilt Monitors follow the same program steps as Shockokee except they promote upright handling at all times.

SHOCKOKEE

IMPLEMENTATION PLAN

Action steps

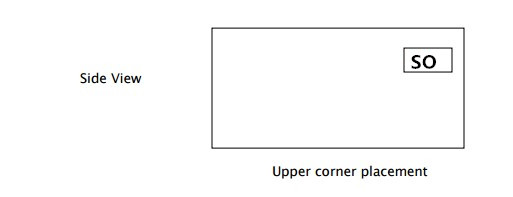

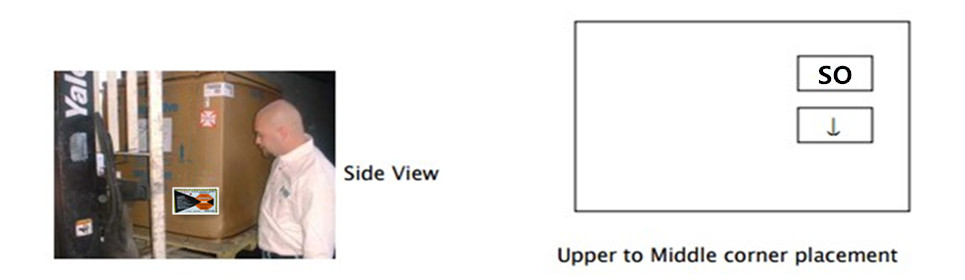

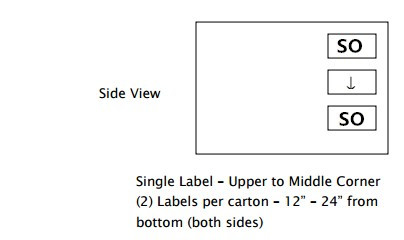

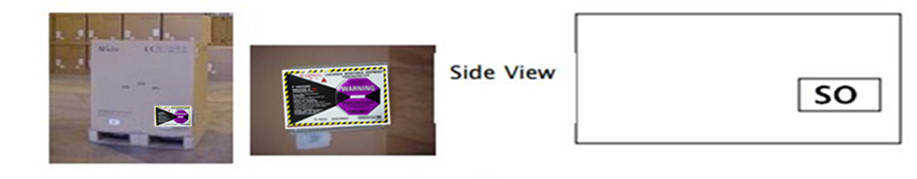

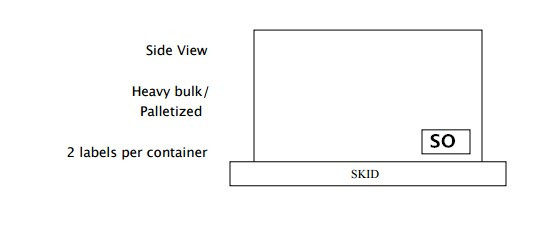

• Inform your people• Inform your carriers • Inform your customers • Introduce the program and monitor the results Shockokee Label Placement • Place the Shockokee label close to the right hand edge • The heavier the shipment, the lower the Shockokee label is placed • Never place the Shockokee label in the middle or on a flexible surface • When the length is twice the width, use two labels on opposite sides, close to the right hand edge LABEL DESCRIPTION PLACEMENT Green – L-30 Upper right hand edge Orange – L-35 Upper right hand edge Red – L-47 Bottom 1/3 of container, right hand edge Purple – L-55 Bottom 1/3 of container, right hand edge Yellow – L-65 Bottom 1/3 of container, right hand edge Alert Message – Place on delivery documents under “Special Instructions”, or as close as possible to where the shipment is signed for when changing hands. Companion Label – Place Shockokee on Companion Label. The Companion label instructs carrier on what to do when the Shockokee indicator is red.

selection guide

Using This Selection Guide…SHOCKOKEE LABEL This selection guide and sensor activation table should always be used a starting point (rule of thumb). Packaging design and construction may affect the correlation between drop height and Shockokee activation. We recommend that you speak to a Shockokee Representative before placing an order. Two things you need to know to select a Shockokee sensitivity: 1. Cubic Meters of shipment (height x width x depth) 2.Weight of shipment.

Cubic Meter = height x width x depth

EXPECTED DROP HEIGHT FOR SHOCKOKEE ACTIVATION HOW DO I KNOW WHICH LABEL TO USE The standard Shockokee labels are available in five sensitivity levels. A selection guide is provided to help you determine which label to use on your shipping containers. 1.Determine the size (volume) of your shipping container in cubic feet (height x width x depth). 2. Determine the total weight, including the item(s) shipped, all packing material and the shipping container itself.Once these two factors have been determined, refer to the ShockokeeSelectionguide forthe appropriate Shockokee label. WHAT IF MY SHIPMENT FALLS ON THE BORDER BETWEEN TWO DIFFERENT SENSITIVITIES ON THE SELECTION GUIDE When variables cause a selection to be borderline, contact your local Shockokee Representative. Typically one should pick a less sensitive sensor (one that requires a higher level drop) due to the psychological inhibition and control qualities Shockokee has over a person. Besides, a higher drop may mean “excessive or abusive” handling which will have a greater probability of damage if activated. If a container is never abused or mishandled, the probability of concealed damage is eliminated. Remember, you are picking a starting point for a Shockokee evaluation program. The final selection must be based on actual performance. Often the “fragility” of the object protected by Shockokee may not be completely defined. The nature of the shock the object will undergo is more complex than generated in most laboratory tests. WHERE SHOULD THE “ALERT STICKER” PROVIDED WITH THE LABEL BE PLACED If possible, the self-adhesive Alert Sticker should be attached to the waybill or packing slip. Alternately, the sticker can be placed adjacent to the Shockokee sensor label on the shipping container. WHERE SHOULD THE LABEL BE PLACED ON THE SHIPPING CONTAINER Shockokee should always be placed on the side – not on the top – of the container. It should be placed at the sturdiest part of the container, i.e. next to the corner of the container, down slightly from the top, where it is most rigid. Do not placethe label in the center of the container. It is also best to use two (2) labelsif the shippingcontainer is twice as long as it is wide – or if the shipment ispalletized. In this case, the labels should be placed diagonally across from eachother on opposite sides of the container. PLACEMENT GUIDES L-30 GREEN SHOCKOKEE SENSOR LABEL = 100 g’s @ 50 msec 1.Used on shipments of 1 lb. to 35-50 lbs. to monitor drops over 36”. Activation range, depending on packaging, can be from 36” to 48”. 2.Used primarily on UPS, RPS, Federal Express or other types of (hand carry) package carriers. 3. Placement of label is in upper right hand corner of box on side nearest packing slip or address label. Side View Upper corner placement  L-35 ORANGE SHOCKOKEE SENSOR LABEL = 75 g’s @ 50 msec 1. Used on shipments of 25 lbs. to 75-100 lbs. to monitor drops of 24” to 36”. 2. Used primarily on Federal Express or other Air Freight carriers, LTL as well as UPS or RPS. 3. Placement of label is in upper right hand corner of box on side nearest packing slip or address label. 4. If item is large or extra sensitive, placement of label can be made from the middle to the upper corner of the side. Side View Upper to Middle corner placement  L-47 RED SHOCKOKE SENSOR LABEL = 50 g’s @ 50 msec 1. Used on shipments of 50 to 300 lbs. to monitor drops from 12” to 24”. Activation usually occurs as follows: a. 50 to 100 lbs. = 18” to 24” b. 100 to 300 lbs. = 12” to 18” 2. Used primarily on Common Carrier, Air Freight or LTL. No UPS – sensor too sensitive for UPS handling. 3. Generally, items over 100 – 125 lbs. should require two (2) labels, particularly if the unit is large, bulky, palletized or very sensitive equipment. 4. Placement should be 12” to 24” from bottom (diagonally across) on opposite sides. 5. Placement of single label shipment can be from the middle to upper corner of container side.  L-55 PURPLE SHOCKOKEE SENSOR LABEL = 37 g’s @ 50 msec 1.Used on shipments 50 – 500 lbs. to monitor drops of 12” to 18”. 2. Used primarily on Common Carrier, Air Freight or LTL. No UPS shipments. 3. Activation usually occurs as follows: a. 50 to 100 lbs - 12” to 18” b. 100 to 500 lbs - 8” to 16” 4. Placement should be a. 50 – 100 lbs. - middle to upper side edge of carton b. 100 – 500 lbs. - 2” to 24” from bottom of pallet or carton  L-65 YELLOW SHOCKOKEE SENSOR LABEL = 25 g’s @ 50 msec 1.Used on shipments over 300 lbs to monitor drops from 6” to12”. 2. Used primarily on Common Carrier, Air Freight or LTL. No UPS – sensor too sensitive for UPS handling 3. Placement should be 12” to 24” from bottom (diagonally across) on opposite sides. Use (2) labels per container.  |

- 上一篇:春节放假通知

- 下一篇:我司商标、专利、版权